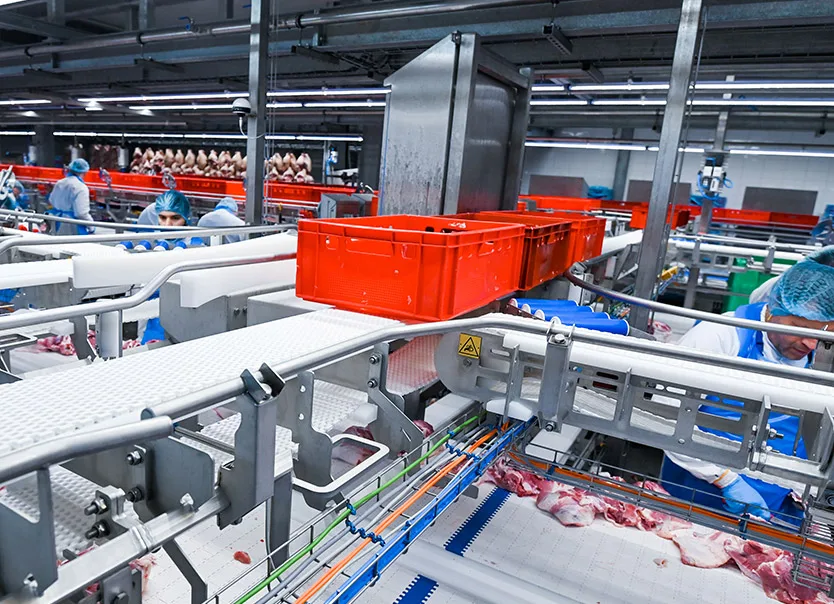

Poultry processing

Experts in the poultry processing industry know DGS as a reliable partner in the field of process optimisation. For years we have been supplying various tailor-made systems to improve processes within chicken abattoirs. From a cooperative standpoint, we identify the different logistical solutions required after the slaughter. Are there any areas for increased efficiency? Where are you missing out on returns? How can you make the work for your personnel more ergonomic? We would like to help answer these and more questions. With DGS you are always assured of:

- Efficient custom made solutions

- Short lines and lasting cooperation

DGS delivers tailor-made solutions. We would like to sit down with you to identify where the points for improvement are within your processes. For example, hygienic transport systems, cooling and freezing systems. However, we go further still; we are also happy to help you optimise your processes within internal logistics, packaging systems, chilling and freezing systems, (de)palletising, pick & place and warehousing.

Personal advice

We are happy to discuss the possibilities with you.

References

Plate freezer pump filling

The use of a pump for filling plate freezers ensures fast and accurate dosing of separator meat, mechanically deboned meat, and other pumpable products. This method minimizes waste and also enables easy and safe palletization and logistics thanks to the uniform blocks. Various layouts are possible, including combinations with hoppers or other filling systems. Additionally, the system is easy to clean.

Read more

Meat processing

Material handeling

Logistic solutions for poultry

A well-oiled process contributes to a higher yield, lower costs and a more sustainable way of working. Are you curious about all the advantages and possibilities that DGS provides? Then contact our specialists. They have all the knowledge in house and will be happy to help you.

- Ergonomic work environment

- High quality meat

- Efficient process

- Optimisation by means of automation and robot techniques

Succes cases

News about this sector

5 reasons to choose Automatic Palletizing

For manufacturing companies, efficiency is key to success. One way to increase efficiency is by automating processes. However, these are often significant investments and as a business owner, you want to ensure that it delivers actual results. In this article, we will discuss five reasons why...

Read moreService by DGS

Maintaining your machines and systems is crucial for a streamlined process. That is why we provide not only tailor-made systems, but also the proper service required. At DGS, we ensure that your systems are maintained properly and efficiently. Does a component need to be replaced or has an unexpected malfunction occurred? Then our specialists have the knowledge and skills to get your operations up and running again as soon as possible. In addition, our experts also offer remote assistance and will gladly draw up a maintenance plan together with you to avoid unforseen maintenance costs.

- Maintenance and repairs

- On-site and remote service